The New AMI Belt Cutter - Design for Manufacturer

The development of the new AMI belt cutter arose out of a clear market demand for a belt cutter that was lighter, easier to use, effortless to repair, and built to withstand harsh working environments. AMI recognized this and partnered with Lean Machine to fill this market gap. In a matter of weeks, our team of engineers was able to deliver a clever new design and a prototype to meet these demands. The result was a sleek, lightweight machine that is exceptionally corrosion-resistant and guards against the build-up of dirt and grime through intelligent design and the use of superior materials.

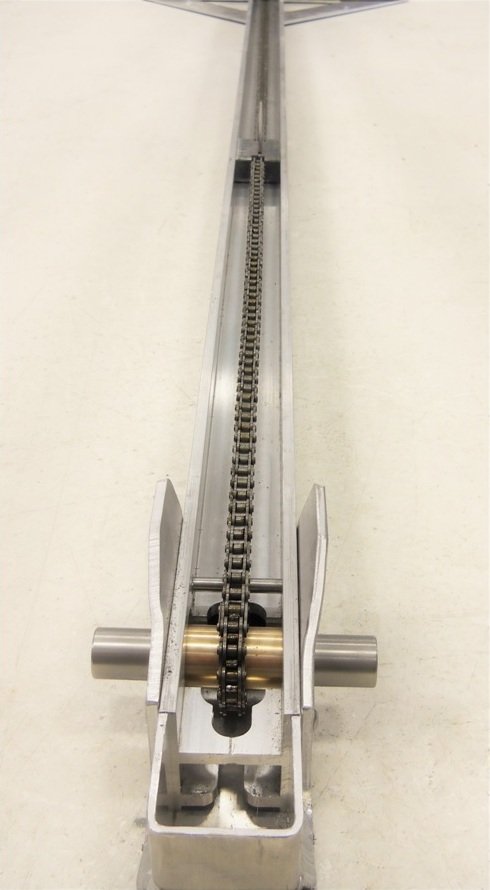

The main body and lid are fabricated from custom aluminum extrusions which allows for a minimal amount of machining and for ease of manufacturing.

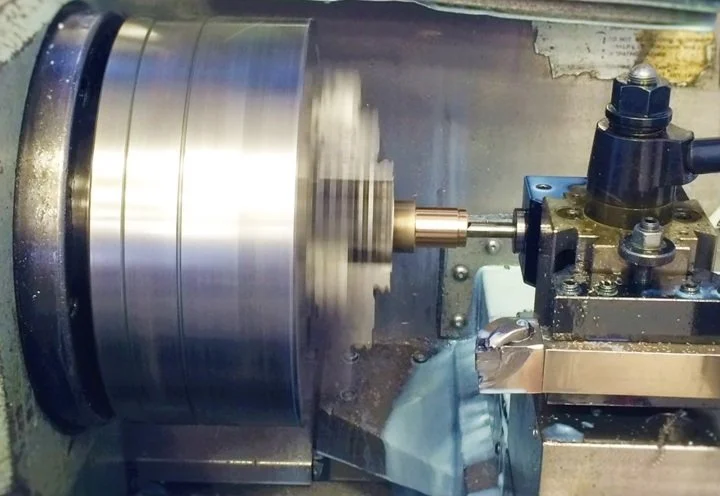

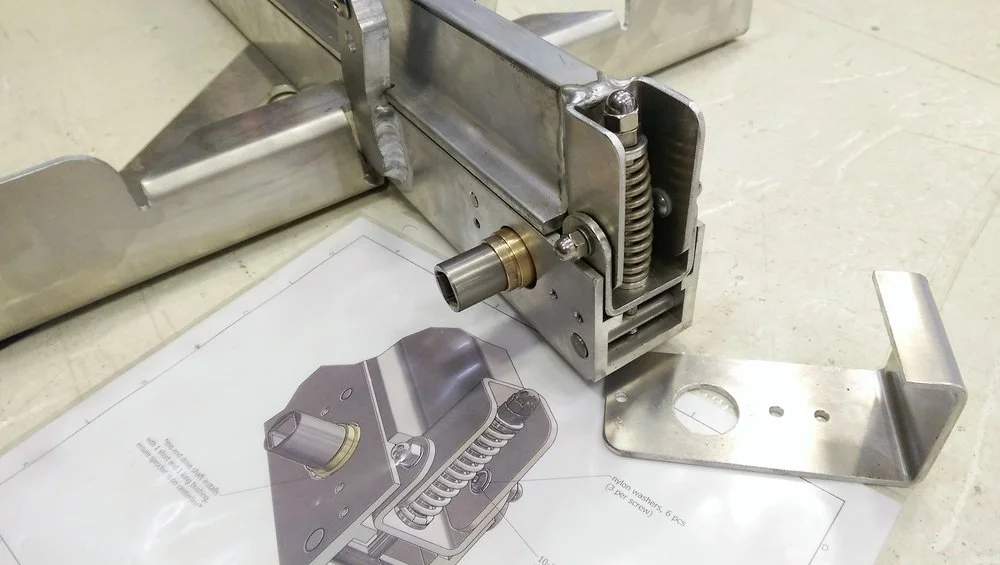

The drive systems at either end are identical and are comprised of just four parts: a machined stainless steel shaft, a custom-made laser-cut gear, and two bronze bushings.

Two stainless-steel springs are located at either end, allowing the belt cutter to instantly conform to any thickness of belt (up to 3/4 of an inch)

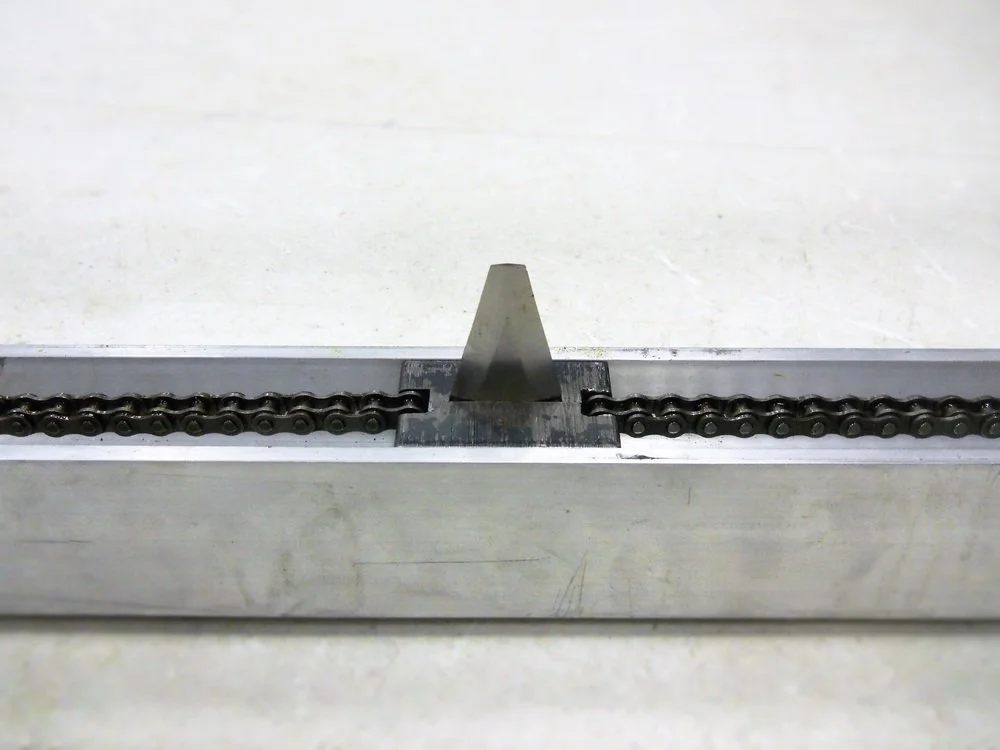

The double-edged blade is made of hardened stainless steel making it extremely durable and corrosion resistant. The blade carriage has been designed for ease of use, making blade replacement quick and painless.

The innovative design and choice of materials make this new belt cutter stand out among the rest, adding significantly to the machine’s performance and longevity.

The beauty of the new AMI Belt Cutter lies in its simplicity. It has been devised to combine the smallest number of moving parts with the highest number of shared parts. The result is a state-of-the-art machine that is highly efficient to manufacture, remarkably easy to service, and maintains smoother functioning for longer.