The Advantages of CNC Router

At Lean Machine we have many different ways to cut metal. When cutting aluminum one of our favorite ways is with a CNC router. The router is extremely cost effective to run, it can cut very thick aluminum, and one of the coolest things is that it can depth cut (cut partially down into the sheet) to do engraving and pocketing. Below is a part that we have designed to take advantage of the router's depth cutting capabilities.

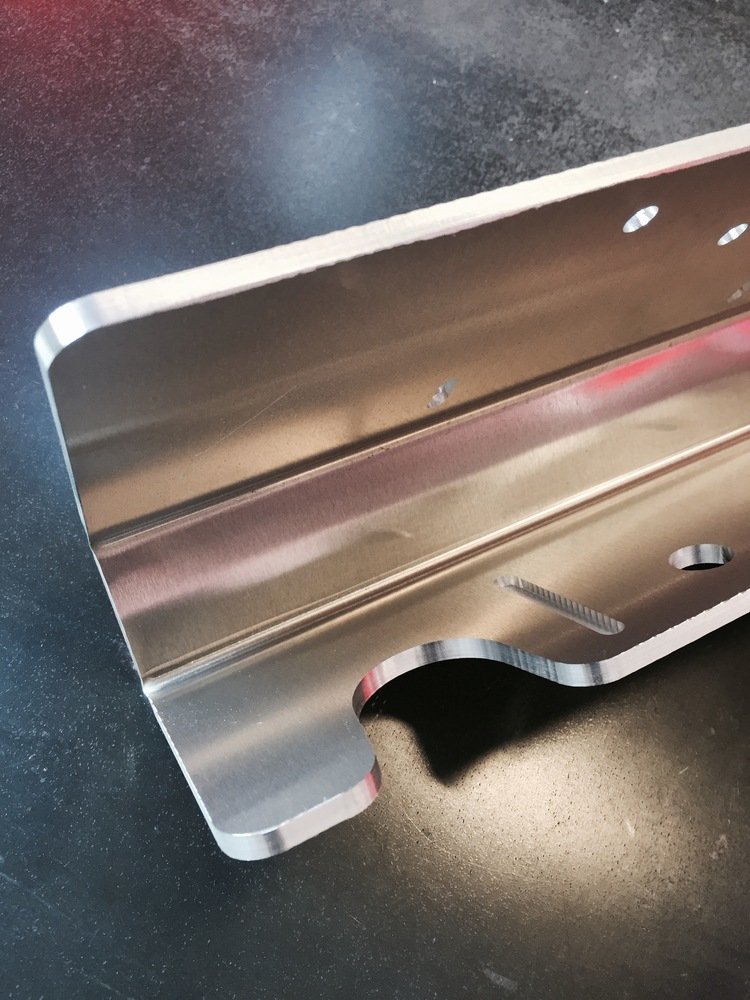

This is the base part of an aluminum assembly that is robotically welded together. The half-depth slot is a way to index the gussets that will be welded in without using an additional jig or measuring and tack welding each one in. As a side note, the finished edge quality is excellent on the Onsrud CNC router.

The gusset is a 3/16" thick 5052 aluminum part that is also cut on the CNC Router. The little tab sticking down seems like it is cut on an odd angle; however, much thought was put into the shape of it. The Robot Cell Operator can easily slide each gusset into place, but they will not fall out when the entire assembly rotates in the robotic jig.

With the final assembly welded together, you cannot see depth cut slots anymore and everything was lined up perfectly for the robot to weld. This design makes for an extremely repeatable part that saves cost for Lean Machine and its customers.